Key features of these devices include ease of field calibration, with the possibility of pre-calibration by the manufacturer.

These devices comply with Atex explosion-proof requirements.

As for applications, the thermal flow switches are suitable for all types of gases and liquids, with the possibility of installation on tanks with pipe dimensions of at least 1/4".

The maximum length of the sensor reaches 3.3 m, allowing installation in any angle, vertical or horizontal.

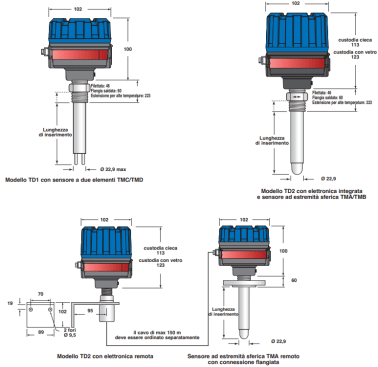

As far as sensor structures are concerned, we offer two variants: the two-element sensor and the ball-end sensor.

TD2

Price per Unit

| Qty | Unit price (Vat excluded) |

Unit price (Vat included) |

|---|---|---|

| 1 | €1,630.00 | €1,988.60 |