POMPE TRAFERIMENTO LIQUIDI & GAS

PERCHE’ SCEGLIERE UNA POMPA PER IL TRASFERIMENTO DI LIQUIDI O GAS RIELS® INSTRUMENTS

Scopri le pompe per trasferimento di liquidi o gas di alta qualità di RIELS® INSTRUMENTS.

Le nostre pompe offrono prestazioni elevate, affidabilità e facilità d'uso per il trasferimento efficiente di liquidi.

Sia che tu abbia bisogno di pompare acqua, olio, carburante o altri fluidi, le nostre pompe sono progettate per soddisfare le tue esigenze.

Con materiali di alta qualità e tecnologie avanzate, le nostre pompe garantiscono un funzionamento senza intoppi e una lunga durata.Scegli la qualità e l'efficienza con le nostre pompe per travaso liquidi. Scegli la qualità e l'efficienza con le nostre pompe per travaso liquidi.

Per spostare un fluido in contrasto alla forza di gravità, è necessaria una pompa che aggiunga energia al moto.

Per spostare un fluido in contrasto alla forza di gravità, è necessaria una pompa che aggiunga energia al moto.

Senza l'energia fornita dalla pompa, il trasferimento del fluido sarebbe impossibile.

Le pompe sono progettate per generare un movimento rotatorio o alternativo che sposta il fluido dalla posizione di partenza alla posizione desiderata.

Ciò consente di superare ostacoli come altezze, lunghezze di tubazioni e attrito.

ESISTONO DIVERSE TIPOLOGIE DI POMPE PER TRAVASO LIQUIDI, TRA CUI LE POMPE A MEMBRANA PNEUMATICHE, LE POMPE ELETTRICHE, LE POMPE VOLUMETRICHE AD INGRANAGGI E LE POMPE CENTRIFUGHE.

CIASCUNA CON LE PROPRIE CARATTERISTICHE E FUNZIONALITÀ.

POMPE PNEUMATICHE

Azionate da aria compressa o gas

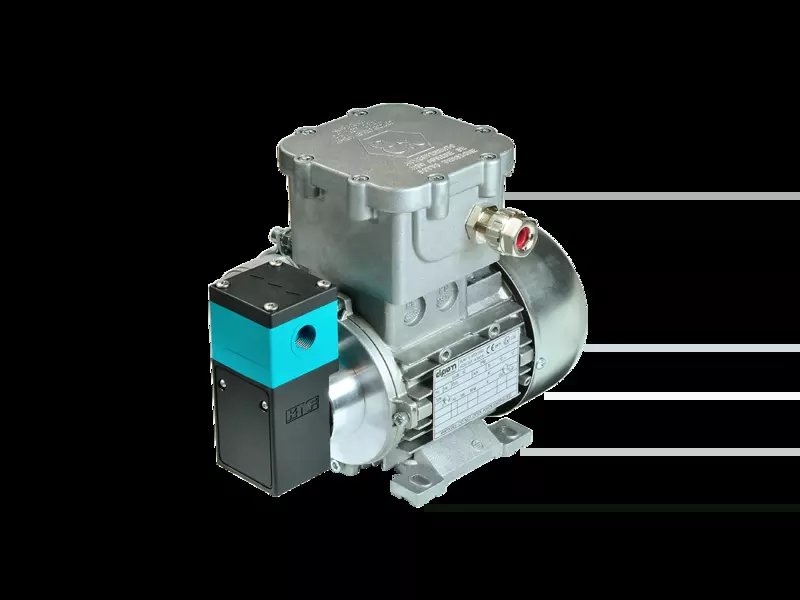

POMPE VOLUMETRICHE

Con tecnologia ad ingranaggi per liquidi viscosi e corrosivi.

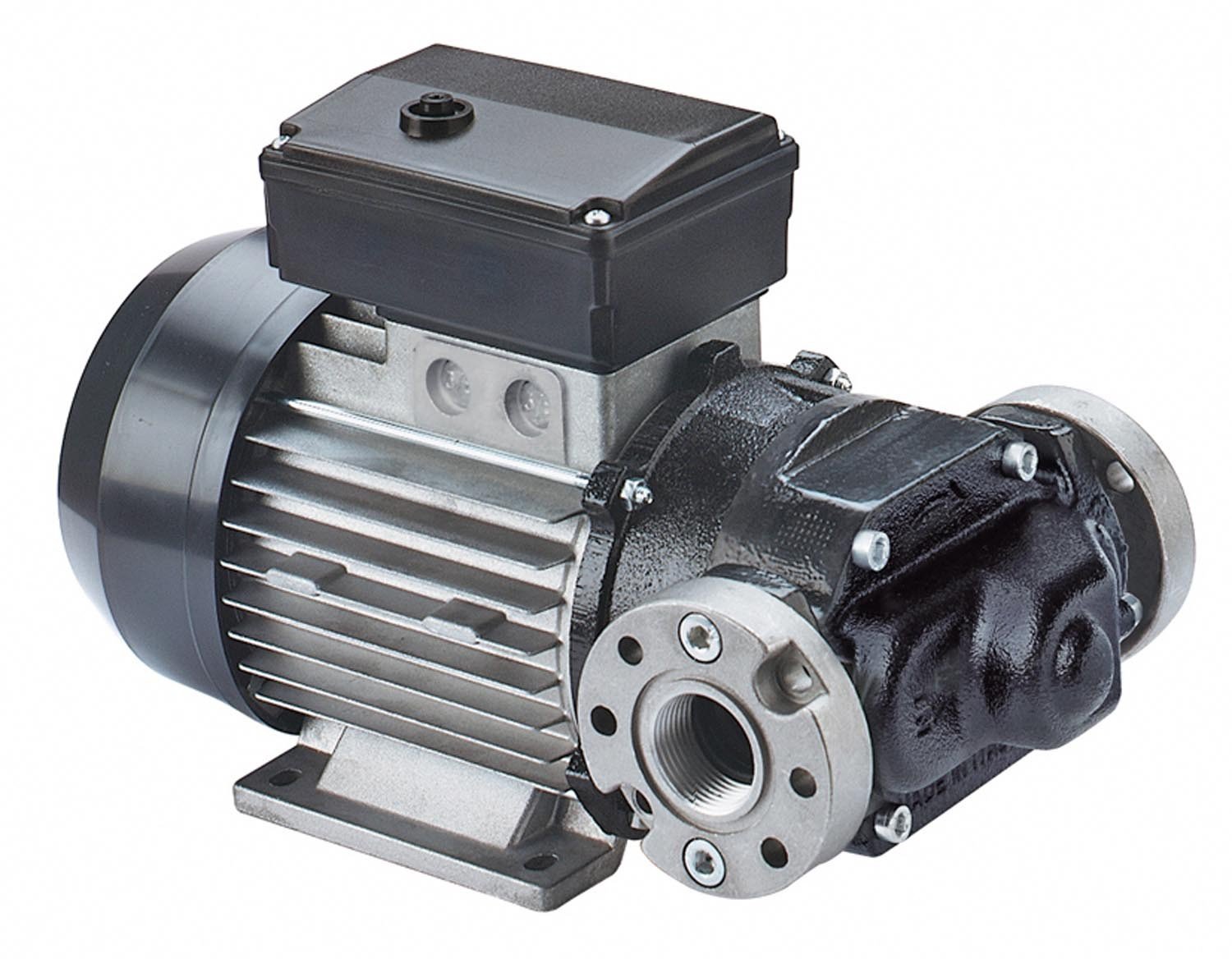

POMPE ELETTRICHE

Tra cui pompe centrifughe e pompe volumetriche

Iniziamo parlando delle pompe a membrana pneumatiche, che sono pompe azionate da aria compressa o gas.

Queste pompe utilizzano una membrana flessibile che si muove avanti e indietro, generando un'azione di pompaggio per trasferire il liquido.

Le pompe a membrana pneumatiche sono conosciute per la loro versatilità e capacità di gestire liquidi di diversa viscosità e contenenti particelle solide. Sono comunemente utilizzate in applicazioni industriali, agricole e di trasferimento di liquidi chimici.

Le pompe elettriche, come suggerisce il nome, sono pompe che utilizzano l'energia elettrica per il loro funzionamento.Queste pompe sono alimentate da un motore elettrico che aziona l'azione di pompaggio.Le pompe elettriche sono disponibili in diverse configurazioni, tra cui pompe centrifughe e pompe volumetriche.Sono ampiamente utilizzate in applicazioni domestiche, commerciali e industriali per il trasferimento di liquidi come acqua, carburanti, oli lubrificanti e altro ancora.

Le pompe volumetriche ad ingranaggi sono caratterizzate da due ingranaggi interni che si ingranano tra loro per creare un'azione di pompaggio. Queste pompe utilizzano i denti degli ingranaggi per spingere il liquido attraverso la camera di pompaggio e trasferirlo al punto desiderato.

Le pompe volumetriche ad ingranaggi sono apprezzate per la loro capacità di gestire liquidi viscosi e corrosivi.

Le pompe volumetriche ad ingranaggi sono apprezzate per la loro capacità di gestire liquidi viscosi e corrosivi.

Sono utilizzate in diversi settori industriali, come l'industria chimica, petrolchimica e alimentare, dove è richiesta una gestione accurata del flusso di liquido.

Le pompe centrifughe sono pompe che utilizzano la forza centrifuga per il trasferimento del liquido.

Queste pompe sfruttano un rotore che ruota ad alta velocità, generando una forza centrifuga che spinge il liquido verso l'esterno e lo trasferisce attraverso un tubo di uscita. Le pompe centrifughe sono ampiamente utilizzate in applicazioni industriali e di approvvigionamento idrico, come impianti di trattamento delle acque, impianti di condizionamento dell'aria e sistemi di irrigazione.

Possono gestire grandi volumi di liquido e sono apprezzate per la loro semplicità di design e manutenzione.

Possono gestire grandi volumi di liquido e sono apprezzate per la loro semplicità di design e manutenzione.