ANALYZERS & SAMPLERS

HOW A RIELS® INSTRUMENTS MUTIPARAMETER ANALYZER WORKS

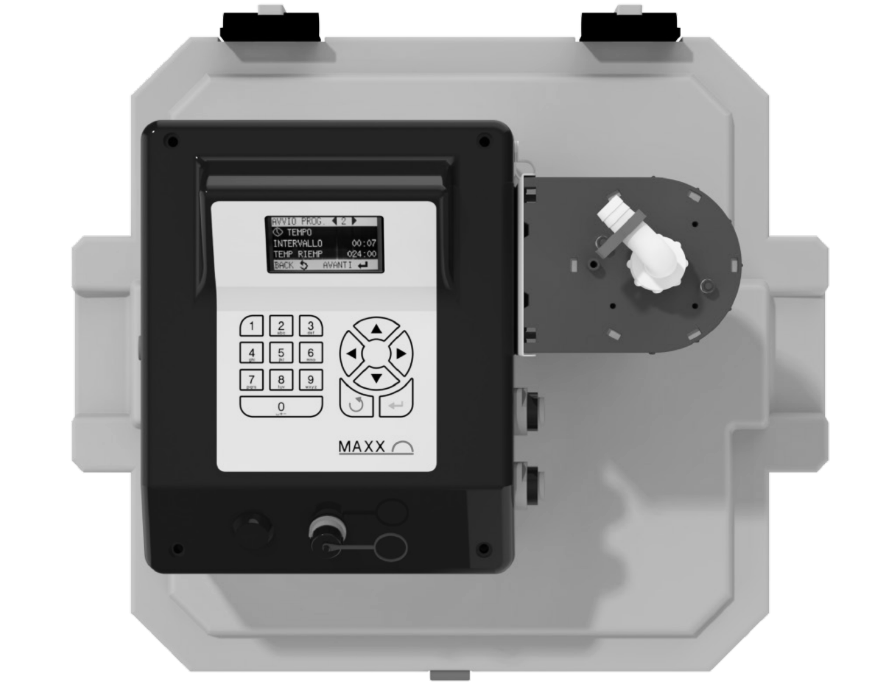

Fixed and portable samplers used for sampling in water, wastewater and industrial applications are based on the vacuum principle.

These samplers allow you to take samples from wells or pipes not subject to pressure, considering the parameters of time, flow rate and event.

The vacuum principle involves using a system that creates a pressure difference inside the sampler, so that the liquid or fluid to be sampled can flow inside the device.

This is done through the use of a pump or vacuum generator, which creates a lower pressure inside the sampler than the external environment.

In this way, the liquid is drawn into the sampler through a tube or sampling system.

In this way, the liquid is drawn into the sampler through a tube or sampling system.

DEPENDING ON THE SPECIFICATIONS OF THE APPLICATION OF USE, IT WILL BE NECESSARY TO DEFINE THE FOLLOWING PARAMETERS:

SAMPLING TIME

Duration of sample collection, which can be programmed based on the desired frequency or specific conditions of the event to be monitored.

SAMPLE CAPACITY

Rate or volume of liquid that can be drawn from the sampler in a given time interval.

ACTIVATING EVENT

Specific action or condition that triggers sample collection, such as an alarm or timed schedule.

MULTIPARAMETER ANALYZERS MEASURE SEVERAL CHEMICAL PARAMETERS SIMULTANEOUSLY USING THE PHOTOMETRIC METHOD.

THESE TOOLS ALLOW YOU TO OBTAIN PRECISE AND RELIABLE RESULTS,

PROVIDING CRUCIAL INFORMATION FOR THE MONITORING AND CONTROL OF PROCESSES AND SYSTEMS.

As for multiparametric analyzers, they are instruments used to measure different chemical parameters simultaneously.

In the context described, multiparametric analyzers are used to measure free chlorine, free ozone, paracetic acid, nitrates, C.O.D. (Chemical Oxygen Demand), hydrocarbons and T.O.C. (Total Organic Carbon).

The measurement of these chemical parameters is carried out using the photometric method, which is based on the ability of some chemical reagents to develop a color proportional to the concentration of a target substance. Photometry exploits the ability of the molecules present in the sample to absorb light, which varies based on the concentration of the substance to be measured.

In the case of free chlorine, a reagent called DPD (N,N-diethyl-p-phenylenediamine) is used which reacts with the chlorine in the water, generating a pink color.

In the case of free chlorine, a reagent called DPD (N,N-diethyl-p-phenylenediamine) is used which reacts with the chlorine in the water, generating a pink color.

Measuring the absorbance of this color allows you to determine the concentration of free chlorine. The same principle is also applied for the measurement of total chlorine, chlorine dioxide, ozone, paracetic acid, bromine and permanganate.

The measurement cycle of photometric analyzers includes several phases.

Initially, the sample enters the measurement cell to be washed and started. Next, the first measurement is taken to calibrate the system (photometric zero).

After that, the specific reagent for measuring the desired parameter is added. The reaction between the reagent and the target substance occurs by stirring the sample.

Subsequently, the developed color is read, which corresponds to the light absorbance of the sample.

This differential measurement between the obtained absorbance value and the reference absorbance value (photometric zero) is processed and converted into a concentration value using specific correlation tables.