VALVES & SOLENOID VALVES

WHY CHOOSE A RIELS® INSTRUMENTS VALVE

Selecting RIELS® INSTRUMENTS as a supplier of Solenoid Valves, Motorized Valves and Pneumatic Valves is a choice based on quality and reliability.

We offer a diverse range of products that meet the needs of multiple industrial sectors, from chemical and petrochemical to food and pharmaceutical.

If you are looking for quality products in fluid or gas control, choose Riels® Instruments as your trusted partner in the field of solenoid valves, motorized valves and pneumatic valves.

SOLENOID VALVES, MOTORIZED VALVES AND PNEUMATIC VALVES ARE FUNDAMENTAL DEVICES FOR THE CONTROL OF FLUIDS IN A WIDE RANGE OF INDUSTRIAL APPLICATIONS.

THEY STAND OUT FOR THEIR OPERATING PRINCIPLE:

MOTORIZED VALVES

Similar to solenoid valves but use an electric motor to open and close the valve. They offer greater actuation force and are suitable for applications with intense duty cycles or those requiring precision control.

SOLENOID VALVES

They use an electrical signal to open or close the valve, allowing precise and rapid control of fluids.

Ideal for applications requiring automatic control based on sensors or timers.

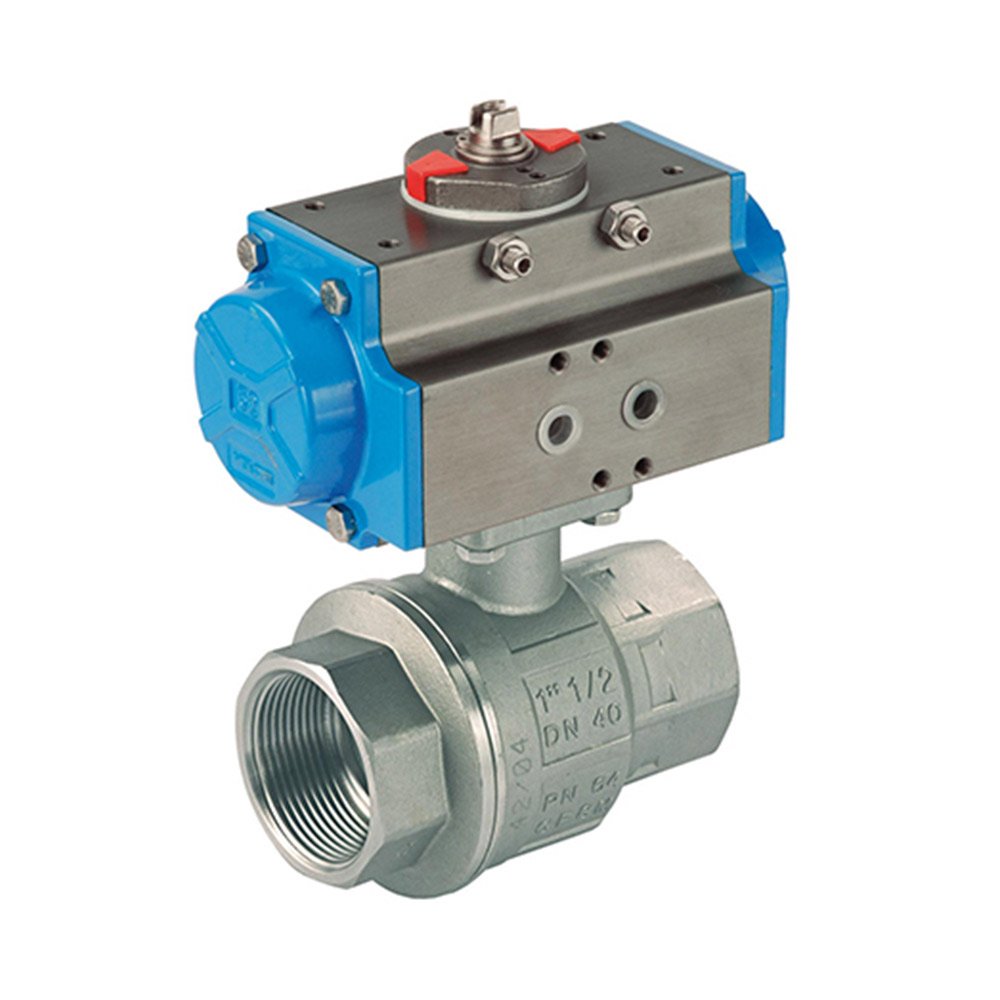

PNEUMATIC VALVES

Operated by compressed air, ideal for applications where rapid response and robust control is required. Often used where electricity may be problematic or to control pneumatic actuators.

A liquid or gas solenoid valve is used to control the flow of liquids or gases in an industrial automation system, irrigation systems, cooling systems, process control applications and much more. It works thanks to the interaction of mechanical and electrical components.

Here's how it works in general:

Electromagnetic Coil: The solenoid valve has an electromagnetic coil wrapped around a ferromagnetic core. When an electrical voltage is applied to the coil, it generates a magnetic field around the core.

Armature or piston: Inside the solenoid valve, there is a component called an armature or piston, usually made of a ferromagnetic material. This armature is positioned so that it can move inside a chamber or tube that controls the flow of the liquid.

Armature or piston: Inside the solenoid valve, there is a component called an armature or piston, usually made of a ferromagnetic material. This armature is positioned so that it can move inside a chamber or tube that controls the flow of the liquid.

Return Spring: Often, there is also a return spring that pushes the armature or piston into a closed position when the coil is not energized.

Orifice or Valve: The orifice or valve is located within the liquid flow chamber. When the armature is in its rest position (when the coil is not energized), the orifice is closed, stopping the flow of liquid.

Orifice or Valve: The orifice or valve is located within the liquid flow chamber. When the armature is in its rest position (when the coil is not energized), the orifice is closed, stopping the flow of liquid.

Electrical control: When voltage is applied to the electromagnetic coil, it creates a magnetic field that attracts the armature towards it, overcoming the force of the return spring. When the armature moves, the orifice opens, allowing liquid to flow through the valve.

Flow Control: The degree of opening of the orifice depends on the intensity of the electrical current supplied to the coil. The higher the current, the greater the magnetic attraction and the wider the orifice is open. In this way, the solenoid valve allows you to precisely regulate the flow of liquid.

Release and close: When the electrical voltage is interrupted, the return spring returns the armature to its closed position, sealing the orifice and stopping the flow of liquid.

Flow Control: The degree of opening of the orifice depends on the intensity of the electrical current supplied to the coil. The higher the current, the greater the magnetic attraction and the wider the orifice is open. In this way, the solenoid valve allows you to precisely regulate the flow of liquid.

Release and close: When the electrical voltage is interrupted, the return spring returns the armature to its closed position, sealing the orifice and stopping the flow of liquid.

A motorized valve is a device that uses an electric motor or motorized actuator to control the flow of fluids (liquids or gases) within a system. These valves are widely used in many industrial and automation applications, allowing precise flow control.

Here's how a motorized valve works:

Electric motor or actuator: The heart of a motorized valve is the electric motor or motorized actuator. This component is connected to the opening and closing mechanism of the valve and controls its movement.

Opening/closing mechanism: The motor is connected to a mechanism that can open or close the valve in response to electrical commands. The type of mechanism can vary depending on the design of the valve, but often involves a shaft or lever that adjusts the opening of the valve.

Electrical Control: The motor is controlled by an electronic system that receives signals or commands from the user or by an automated control system. These commands determine the opening or closing of the valve, as well as its intermediate position if necessary.

Electrical Control: The motor is controlled by an electronic system that receives signals or commands from the user or by an automated control system. These commands determine the opening or closing of the valve, as well as its intermediate position if necessary.

Feedback Sensors: Many motorized valves are equipped with feedback sensors that provide information about the valve's current position. These sensors allow the control system to precisely monitor and adjust the valve position as needed.

Fluid Flow: When the engine opens the valve, fluid can flow through the valve opening. The size of the opening can be adjusted continuously or in discrete steps, depending on the valve type.

Fluid Flow: When the engine opens the valve, fluid can flow through the valve opening. The size of the opening can be adjusted continuously or in discrete steps, depending on the valve type.

Direction Control: In some applications, motorized valves can also be used to control the direction of fluid flow, allowing fluid to pass in a specific direction or blocking it based on system needs.

A pneumatic valve is a device used to control the flow of compressed air or other gases in a pneumatic or hydraulic system. These valves are essential for a wide range of industrial and automation applications, allowing you to precisely regulate the flow of air or gas to operate actuators, control devices and other equipment.

This is how a pneumatic valve works:

Valve body: The pneumatic valve has a body that contains all the necessary components. The body is designed to allow the passage of air or gas and to accommodate the control components.

Actuator or Piston: Inside the valve, there is an actuator or piston connected to a butterfly valve or ball valve. This actuator responds to changes in air or gas pressure and regulates the opening or closing of the valve.

Pressure Source: A compressed air tank or high pressure gas source is connected to the pneumatic valve. Compressed air or gas is supplied to the valve through a duct..

Pressure Source: A compressed air tank or high pressure gas source is connected to the pneumatic valve. Compressed air or gas is supplied to the valve through a duct..

Pneumatic Controls: Pneumatic valves are controlled by pneumatic devices, such as solenoids or pressure switches. These devices send pneumatic signals to the valve to open, close or adjust its position.

Air Flow: When pneumatic pressure is applied, the actuator or piston responds by opening or closing the valve. This changes the flow of air or gas through the valve itself.

Air Flow: When pneumatic pressure is applied, the actuator or piston responds by opening or closing the valve. This changes the flow of air or gas through the valve itself.

Return or release: When the pneumatic signal is interrupted or reversed, the actuator or piston returns to its rest position, returning the valve to its closed position. This stops the flow of air or gas.