CGR-Fx-G10-DN50-1.100-AL-PN16-BF

The CGR-Fx Rotary Piston Gas Meter is an advanced volumetric meter designed to offer high-precision measurements. This device finds use in both gas transportation and distribution, as well as serving as a sample meter within calibration facilities. Its operation is based on the flow of gas through chambers defined by shaping. The pistons are set in motion by the gas flow. The rotation of the pistons is transmitted to the counter by means of a magnetic coupling that allows the inside with the outside of the counter to be completely isolated.

A distinctive feature is the arrangement of the measuring cartridge, which is separated from the outer body to preserve it from potential mechanical stresses caused by flange misalignment. This design, together with the precision machining of the parts that minimizes the distance between the rotors, makes it possible to minimize pressure drop and provide a wide measuring range.

All serviceable parts, such as the oil level sight glasses, oil insertion plug, numerator, and pulse generator, are located at the front of the meter, allowing installation close to the rear wall.

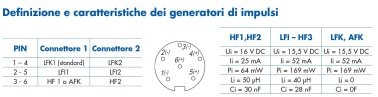

The device offers two pressure sockets, a thermometer pocket and up to four HF pulse generators. It complies with EN12480 standards, as well as being approved according to MID (Metrology Instruments Directive), PED (Pressure Equipment Directive) and ATEX (Atmosphères Explosibles).

In the standard setup, the meter is equipped with two BF pulse generators (LFK). Upon request, two MF sensors (LFI1-LFI2), two HF sensors (HF1-HF2) and one AFK anti-fraud sensor can be obtained. Lubrication with Lubricant L12, with a viscosity of 12 mm²/s at 20°C, is recommended in order to ensure proper operation and durability of the counter over time.

CGR-Fx-G10-DN50-1.100-AL-PN16-BF

Price per Unit

| Qty | Unit price (Vat excluded) |

Unit price (Vat included) |

|---|---|---|

| 1 | €1,344.00 | €1,639.68 |

In this section you will find all the variants available for this model. Improve your configuration with the drop-down menus below, select the desired quantity and click ADD TO CART

The price displayed refers to a specific configuration and varies based on the options selected.