CGT-02-G400-DN100-1.20-PN16-2BF+1HF-T

The operation of the turbine counter is based on the idea of proportionality between the amount of gas passing through the counter and the number of revolutions of the impeller. The CGT-02 uses a mechanical/magnetic transmission system to activate the counting unit, located at the top of the meter. Here, the volume of gas that at operating conditions is displayed.

The accuracy of the bearings, together with the precise tolerances of all measuring parts, help to minimize pressure losses. In addition, the application of a flow rectifier further helps in this regard. The measuring cartridge is separated from the external meter body, which preserves it from any mechanical stresses caused by imperfect flange alignment. The cartridge is fully replaceable, ensuring easy maintenance.

These meters comply with various approvals, such as MID, ATEX and PED, and meet the EN12261 standard. Their construction follows the guidelines of ISO 9001 and meets ISO 9951 DIN 33800. They also meet E2 - M2 environmental requirements.

These meters are available in different sizes from DN50 to DN400. The standard ratio is 1:20 standard but there is an option to request the rangiability version of 1:30.

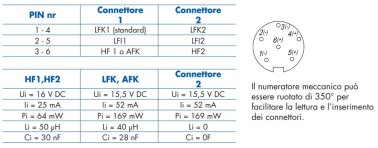

Counters CGT-02 are dated as standard with an anti-fraud reed contact low-frequency pulse lance for fiscal volumetric measurements. Up to four NAMUR-type high-frequency pulse launchers can be added.

CGT-02-G400-DN100-1.20-PN16-2BF+1HF-T

Price per Unit

| Qty | Unit price (Vat excluded) |

Unit price (Vat included) |

|---|---|---|

| 1 | €2,345.00 | €2,860.90 |

In this section you will find all the variants available for this model. Improve your configuration with the drop-down menus below, select the desired quantity and click ADD TO CART

The price displayed refers to a specific configuration and varies based on the options selected.